Foshan Zhenyang Automation Science And Technology Co.,

- Home Page

- Company Profile

-

Our Products

- Hot Chamber Die Casting Machine

- Door Handles Die Casting Machine

- Die Casting Sprue Seperator Conveyor And Roller

- Zipper Slider Die Casting Mould

- Hot Chamber Die Casting Machine

- Hot Chamber Magnesium Die Casting Machine

- Zinc Conduit Connector Die Casting Machine

- Zipper Slider Die Casting Machine

- Faucet Handle Die Casting Machine

- Furniture Screw Die Casting Machine

- Fingerprint Lock Die Casting Machine

- Zinc Medals Die Casting Machine

- Zinc Ashtray Die Casting Machine

- LK Die Casting Machine Zinc Melting Furnace

- LK Die Casting Machine Energy Saving Zinc Melting Furnace

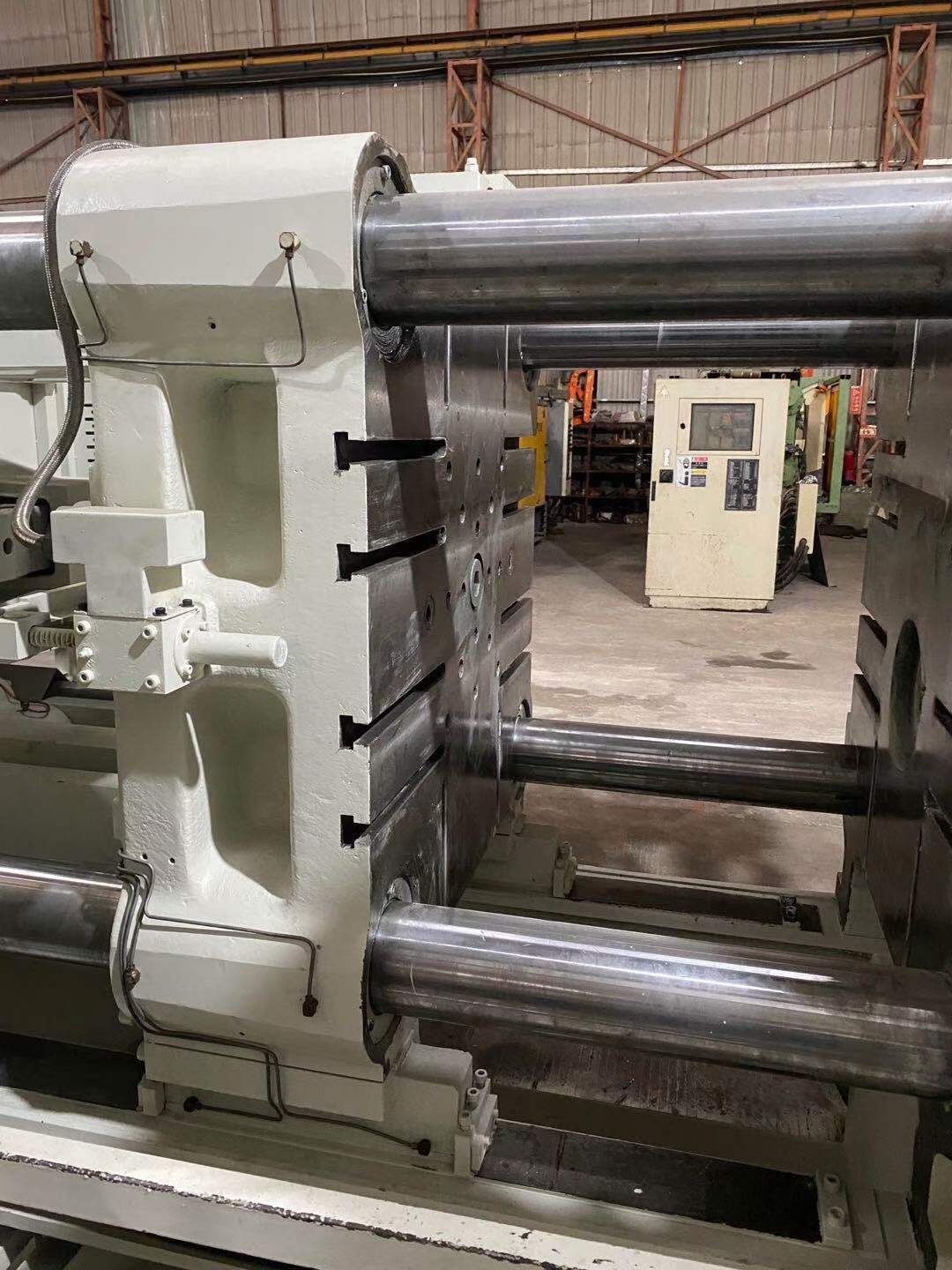

- Cold Chamber Die Casting Machine

- Real Time Control Die Casting Machine

- LK Die Casting Machine Conveyor

- Motorcycle Brake Handle Die Casting Machine

- Magnesium Cold Chamber Die Casting Machine

- Brass Die Casting Machine

- Washing Machine Spider Die Casting Machine

- Streetlight Housing Die Casting Machine

- Servo Motor Control Die Casting Machine

- Street Lamp Housing Die Casting Machine

- Biomass Aluminium Melting Furnace

- Aluminium Office Chair Base Die Casting Machine

- Motorcycle Break Shoe Die Casting Machine

- Non-stick Cook Pot Die Casting Machine

- Streetlight Housing Die Casting Mould

- Steering Wheel Die Casting Machine

- Smartwatch Housing Die Casting Machine

- USB Housing Die Casting Machine

- LPG Valve Die Casting Machine

- Road Stud Die Casting Machine

- Ceiling Fan Cover Die Casting Machine

- Vertical Die Casting Machine

- YIZUMI Die Casting Machine Conveyor

- 130T Cold Chamber Die Casting Machine

- Die Casting Machine Auto Ladle

- Die Casting Machine Automatic Extractor

- Die Casting Machine Vertical Sprayer

- Die Casting Machine Servo Sprayer

- Die Casting Machine Automatic Sprayer

- Hot Chamber Die Casting Machine Extractor

- Release Agent Mixer

- Shot Beads Dispenser

- Used Hot Chamber Die Casting Machine

- Used YIZUMI 400T Hot Chamber Die Casting Machine

- Used Lk 160t Hot Chamber Die Casting Machine

- Used Lk 200t Hot Chamber Die Casting Machine

- Used Lk 88t Hot Chamber Die Casting Machine

- Used LK 100T Hot Chamber Die Casting Machine

- Used Lk 30t Hot Chamber Die Casting Machine

- Used Yizumi 200t Hot Chamber Die Casting Machine

- Used Yizumi 280t Hot Chamber Die Casting Machine

- Used LK 50T Hot Chamber Die Casting Machine

- Used Lk 280t Hot Chamber Die Casting Machine

- Used LK 130T Hot Chamber Die Casting Machine

- Infrared Wave Zinc Melting Furnace

- Used Cold Chamber Die Casting Machine

- Used Lk 400t Cold Chamber Die Casting Machine

- Used Lk 800t Cold Chamber Die Casting Machine

- Used TOSHIBA 650T Die Casting Machine

- Used Yizumi 300t Cold Chamber Die Casting Machine

- Used Lk 280t Cold Chamber Die Casting Machine

- Used LK 630T Cold Chamber Die Casting Machine

- Used Lk 700t Cold Chamber Die Casting Machine

- Used Toshiba Die Casting Machine

- Used TOYO 350T Cold Chamber Die Casting Machine

- Used Buhler 530T Die Casting Machine

- Used TOYO 250T Die Casting Machine

- Used YIZUMI 500T Cold Chamber Die Casting Machine

- Used Lk 160t Cold Chamber Die Casting Machine

- Used Yizumi 180t Cold Chamber Die Casting Machine

- Used Yizumi 400t Cold Chamber Die Casting Machine

- Used Yizumi 650t Cold Chamber Die Casting Machine

- Used Yizumi 800t Cold Chamber Die Casting Machine

- Used TOYO 125T Cold Chamber Die Casting Machine

- Used Toshiba 350T Die Casting Machine

- Used Toshiba 250T Die Casting Machine

- Used UBE 250T Die Casting Machine

- Used LK 200T Cold Chamber Die Casting Machine

- Used ZITAI 420T Die Casting Machine

- Used YIZUMI 900T Cold Chamber Die Casting Machine

- Used YIZUMI 1250T Cold Chamber Die Casting Machine

- Die Casting Machine Spare Parts

- LK Die Casting Machine Gooseneck

- Die Casting Machine Laser Plunger Tip

- Zhenli Die Casting Machine Gooseneck Heater

- Hot Chamber Die Casting Machine Plunger Ring

- Hot Chamber Die Casting Machine Nozzle Body

- Hot Chamber Die Casting Machine Nozzle Heater

- Hot Chamber Die Casting Machine Gooseneck Heater

- Hot Chamber Die Casting Machine Gooseneck

- Cold Chamber Die Casting Machine Shot Sleeve

- Cold Chamber Die Casting Machine Plunger Tip

- Aluminium Die Casting Release Agent

- Aluminium Die Casting Copper Ring Plunger Tip

- Silicon Carbide Graphite Crucible

- Die Casting Lubrication Beads

- Die Casting Spray Gun

- Aluminium Melting Refining Flux Powder

- LK Die Casting Machine Nozzle Heater

- LK Die Casting Machine Gooseneck Heater

- Zhenli Die Casting Machine Nozzle Heater

- HISHINUMA Die Casting Machine Gooseneck

- 7.5T Die Casting Machine Melting Pot

- LK88T Die Casting Machine Melting Pot

- LK88T Die Casting Machine Gooseneck

- LK18T Die Casting Machine Melting Pot

- Aluminium Melting Furnace

- Robotic System

- Hot Chamber Die Casting Machine

- Contact Us